ABOUT R&D LEVERAGE US

True Class 101+ mold manufacturer

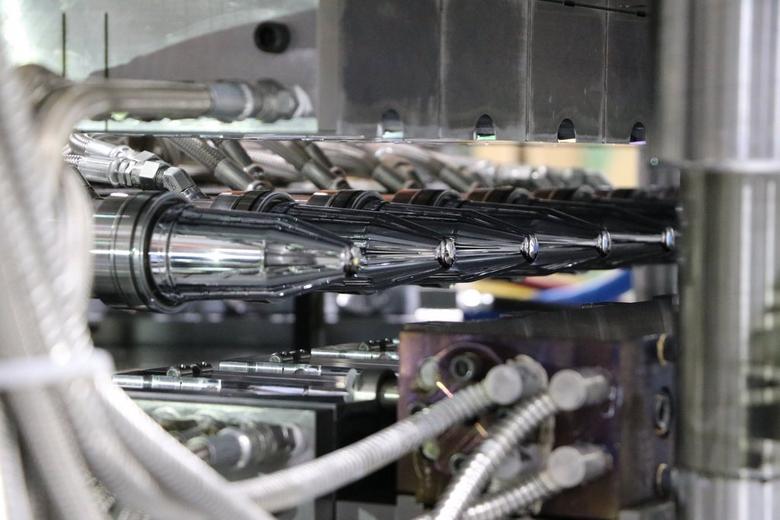

For nearly five decades, R&D/Leverage has been a world leader in the injection stretch blow mold (“ISBM”) and injection blow mold (“IBM”) industries. The Company has been granted 35 patents for technologies related to ISBM and IBM blow molds, and believes that no other company in the world can match its engineering, manufacturing and sampling knowledge and IP in these niche markets.

In addition, the Company is now an industry leader in custom injection mold building and is known for engineering true class 101+ multi-cavity molds, primarily for the medical, consumer and industrial industries. R&D/Leverage’s custom injection team specializes in large, multi-cavity molds with complex actions that produce tightly tolerance parts.

Across all business segments, R&D/Leverage prides itself on tackling its customers’ most difficult and complicated jobs – those that other mold manufacturers cannot, or will not, do. The Company doesn’t just design molds, it engineers them.

The Company tests, samples and validates all molds in-house, via its Product Solutions Labs. These PSL labs are segmented by mold type – ISBM, IBM and custom injection – and include process optimization studies and extensive process documentation, allowing us to recreate our process around the customer’s needs. When not sampling molds, R&D/Leverage utilizes its state-of-the-art ISBM, IBM, preform, and injection molding machines for short and medium production runs for its customers.

The Company operates from 188,000 sq. ft. of manufacturing facilities on a 13-acre campus in Lee’s Summit, MO.

Services

Injection Molding

Mold Design

Mold Making: Injection Blow Molds

Mold Making: Injection Molds

Mold Making: Injection Stretch Blow Molds

Mold Repair

Molding - ISBM and IBM

Molding - Preform

Prototype Parts

Prototype & Unit Tooling

Reverse Engineering

Sampling

Scheduled Mold Maintenance

Spare Components

Turnkey Mold Builds

Vendor Managed Inventory

Capabilities

3D Part Scanning

CMM

CNC Live Tooling

CNC Milling

CNC OD/ID Grinding

CNC Turning

Finite Element Analysis

Laser Welding

Mold Flow Analysis

Polishing

Sinker EDM

Tight Tolerance Round Grinding

Tight Tolerance Surface Grinding

Wire EDM

More News

We know molds.TM

©2024 ADLER INDUSTRIAL SOLUTIONS INC.

Contact Us

We want to learn more about you and how we can help.

Main Office

One Applied Parkway

Omaha, NE 68154

info@adlertooling.com

(415) 329-6877